Providing customers with safe and secure material handling equipment

Quality Management System

We are working to improve the quality of our operations through the ISO 9001 quality management system (QMS) and other such systems. We conduct internal audits twice a year and undergo an external examination by a certification body once a year to confirm whether ISO standards are being effectively used as a tool for business improvement by maintaining and improving the QMS and continuously improving it.

In addition, we regularly conduct ISO Internal Auditor Skill Improvement Training to support the competence of internal auditors and provide Internal Auditor Training as a means of securing internal auditors.

Quality Policy

We formulated the following four quality policies and made them known to all employees working at our company. In keeping with this policy, we strive to ensure the continual improvement of the quality of all our operations as well as the development and manufacture of our products.

- 1. We will provide safe and secure products and services to customers and strive to improve customer satisfaction.

- 2. We will strive to eliminate non-conforming products and will always take prompt and effective action should such an instance arise.

- 3. We will raise the quality awareness of all our employees and work together with related parties to ensure the highest levels of quality.

- 4. We will continuously improve our quality management system.

Initiatives for quality improvement

Each November, during Quality Month, we undertake a variety of initiatives designed to enhance awareness of quality and encourage the adoption of comprehensive quality control practices.

We held the Measurement Skills Competition and the Vehicle Inspection Competition to evaluate current practices, assess proficiency in vehicle inspections, and promote skill enhancement. Additionally, we conducted the Comprehensive Skills Competition at the Shiga Plant, with the aim being the acquisition of foundational knowledge and high-quality skills by workers in welding, mechanics, painting, assembly, and measurement to be deployed in the production of better products.

In addition, we strive to cultivate an environment that promotes human resource development and skill enhancement through these competitions.

Product options contributing to enhanced safety

In the belief that all operations can be performed safely and that anyone can easily operate our equipment, we provide products incorporating features carefully selected for safety and security. In 2022, we launched new S-Assist options for the ALESIS Counterbalanced Electric Forklift; these features safely and comfortably support driving operations for the benefit of the operator. The two outstanding features of these options are Hill Stop Assist and Speed Control Assist.

Hill Stop Assist prevents the vehicle from rolling backward when the operator switches between the accelerator and the brake, contributing to easy and safe starting on a slope.

Speed Control Assist is a proprietary feature that maintains a constant speed as the operator is lightly stepping on the accelerator. We have received positive comments from customers who praise this feature for enabling the operator to concentrate on the surroundings without being distracted by accelerator operation.

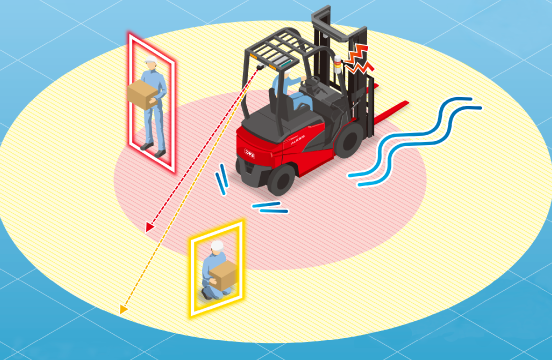

Furthermore, we are offering a second new option: OmniEye® an AI-powered human detection system. OmniEye® incorporates a human detection function through two cameras attached to the front and rear of the vehicle to detect and warn of surrounding workers. These cameras prevent collisions by monitoring areas that are difficult for the operator to see. As a safe and secure product that can be mounted on all small forklifts, we provide this innovation in collaboration with its developer, Regulus Co., Ltd. Two additional enhanced safety features are also available as options: the Good Running System, which reduces shock and vibration during bump operation; and the LVS Forklift Operation Management System, which contributes to efficient vehicle operation and safety visualization.

Providing a complete selection of services

In order to provide our customers with safe, secure, and reliable services, we hold training sessions for our Group service technicians in Japan and outside Japan.

In Japan, the curriculum includes rank-based training targeted to specific careers and experience levels as well as technical training that coincides with product launches. We also hold meetings for the sharing of defect information and countermeasures in order to accommodate the increasing sophistication of technology along with the increasing complexity of vehicle control systems.

We operate a service technician certification system to certify the service personnel of our distributors outside Japan. These service technicians can learn step-by-step at all levels from basic to advanced, which enables these individuals to acquire the necessary maintenance technical skills with assurance. Service technicians who meet the knowledge and skill requirements are granted new qualifications, which leads to increased motivation. The number of certified service technicians is increasing year by year (see graph), supporting our service technicians in improving their skills and capabilities.

Trend in Number of Certified Service Technicians

who are certified as “Service Technicians.”

Safety awareness initiatives

Our sales companies provide safety awareness and safety enhancement training to our customers in order to prevent accidents involving forklifts in industrial settings. We have made available a variety of tools, including our own self-produced safety DVDs, to promote safety initiatives. In addition, we are working to increase safety awareness throughout society by holding safety seminars tailored to customer needs and distributing safety awareness posters in conjunction with the National Safety Week campaign sponsored by Japan’s Ministry of Health, Labour and Welfare.

Safety Seminars Held

Holding driving lessons

Those engaged in the operation of forklifts with a capacity of 1 tonne are required by the Industrial Health and Safety Act to complete an operator skills course. As a manufacturer of forklifts and shovel loaders that is registered as a training organization under the Director of Japan’s Labour Bureau, we hold seminars at two locations in Japan and place the highest priority on driver safety.